Here's How 3D Printers Work

- Locanam 3D Printing

- Feb 5, 2024

- 5 min read

Perhaps one of the oldest dreams of a of science fiction has been the prospect of generating matter from nothingness. The concept of crafting tangible, enduring objects seemingly out of thin air has long captivated imaginations, offering a glimpse into a future where the constraints of scarcity are overcome. While the reality may not yet match the fantastical Replicator devices depicted in "Star Trek," contemporary manufacturing technologies are far from stagnant in their pursuit of innovation.

While the concept may not involve conjuring items from thin air, the advent of 3D printing has revolutionized manufacturing by providing increased versatility in producing objects of diverse shapes and sizes. This technology extends beyond mere replication to enable individuals to utilize 3D printers for crafting their own creations. Whether it's fashioning standalone small items or contributing components to a larger structure, the process, though sounding complex, becomes relatively straightforward with a grasp of the functioning principles behind different types of 3D printers.

3D printing in general

The process of 3D printing, often referred to as "additive manufacturing," distinguishes itself from traditional manufacturing methods categorized as either subtractive or formative. Unlike subtractive manufacturing, which involves carving out the desired form from a solid block of material using tools like milling machines, 3D printing builds objects layer by layer. Similarly, it differs from formative manufacturing, where materials are molded or shaped directly to achieve the desired product, such as pouring molten plastic into molds for doll production. This innovative approach of additive manufacturing allows for precise and intricate designs to be created by adding material gradually, revolutionizing the landscape of production methods.

Additive manufacturing, often referred to as 3D printing, stands in contrast to subtractive manufacturing methods. Instead of removing material to shape an object, additive manufacturing involves the incremental addition or alteration of material in layers to achieve the desired form. The specific technique and the choice of materials employed vary based on the type of 3D printing device utilized.

Fused Deposition Modeling

Fused Deposition Modeling, often referred to as "FDM," stands out as a widely utilized 3D printing method, particularly popular among consumer-grade devices. This technology is so straightforward that it has been adapted for home use, making it accessible to a broader audience. At the heart of FDM printing lies the utilization of thermoplastic filament—a slender thread of specifically formulated plastic that exhibits remarkable responsiveness to temperature-induced shaping.

In the process of 3D printing using Fused Deposition Modeling (FDM) technology, a filament thread undergoes controlled heating, transitioning into a semi-solid state. This heated filament is then guided through a temperature-regulated extrusion head, where it is meticulously deposited onto a printing surface. The plastic material is precisely distributed and layered based on your design specifications, with intermittent stops and starts to introduce gaps in the model. Analogous to piping icing onto a cake to form a rose, this method operates on a smaller and more intricate scale.

The resulting models from an FDM printer may exhibit a somewhat coarse texture, displaying visible lines between the individual layers. Despite the semi-solid nature of the plastic, slight gaps may exist within the strands. These characteristics make FDM printers particularly suitable for the fabrication of physical prototypes and proofs of concept. This technology provides a practical means of materializing designs with a focus on precision and feasibility, though the finished products may display surface variations due to the layering process.

SLA (Stereolithography)

Stereolithography, commonly known as SLA, stands out as the pioneer in 3D printing, tracing its roots back to the 1860s with the inception of the "photo sculpture method." However, it wasn't until the 1980s that SLA evolved into a recognized and viable technology. This innovative 3D printing technique revolves around the use of resin, a prototypical plastic, in the fabrication process. Through selective curing and hardening, the resin transforms into a durable and well-defined plastic structure. This pioneering approach in additive manufacturing has played a crucial role in shaping the landscape of modern 3D printing technology.

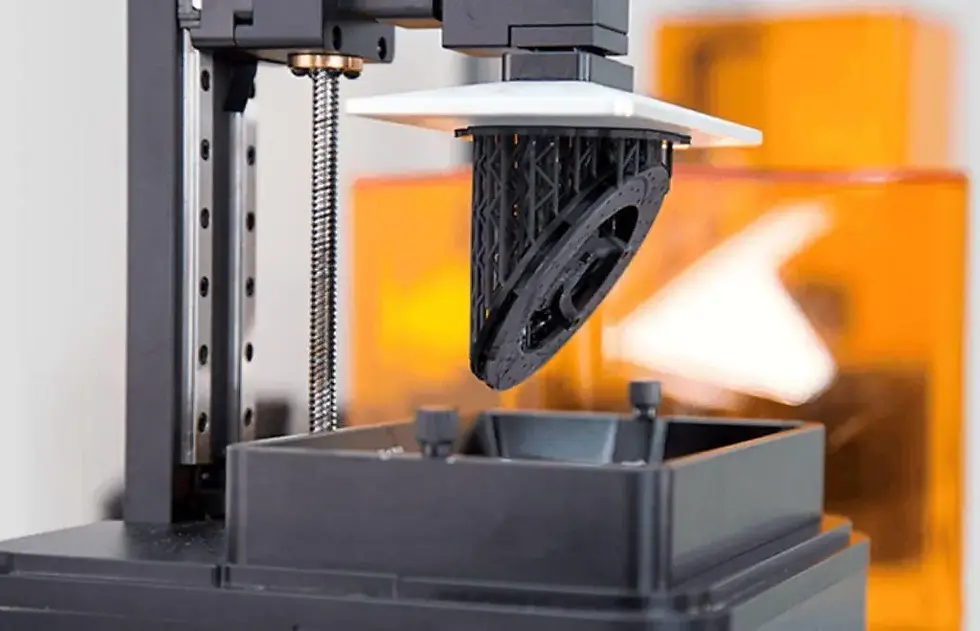

The liquid resin employed in this technique exhibits a remarkable responsiveness to ultraviolet radiation. A short exposure to a UV beam is all it requires for the resin to undergo solidification. Employing an SLA printer involves directing this UV beam in controlled bursts into a reservoir of resin configured in the desired object's shape. With each burst of the beam, the resin undergoes solidification, causing the plastic mold to ascend and emerge from the reservoir. Subsequently, removing any surplus residue results in the completion of your model.

Depending on the intricacy of the model being created and the specifications of the SLA printer in use, specialized support structures may be automatically incorporated into the resin along with the mold. These supports serve to uphold the structure during the printing process. Once the curing process is complete, the support structures can be easily removed. The precision of the UV beam facilitates the fabrication of highly complex shapes, such as a detailed model of the human heart or an impression of teeth for the production of dental aids.

Selective Laser Sintering (SLS)

While the majority of 3D printing methods commonly involve the use of various plastic materials, there are exceptions to this trend. Take, for instance, the selective laser sintering (SLS) technique, which diverges from the norm by employing powdered polymers. One might initially question the feasibility of creating robust objects from powder, but the ingenious application of a laser addresses this skepticism.

In an advanced manufacturing process known as Selective Laser Sintering (SLS), a substantial quantity of polymer powder undergoes a meticulous transformation within a specialized chamber. The technique involves precision as a high-powered laser selectively targets specific areas on the powder, causing instantaneous fusion layer by layer. This process results in the formation of a robust structure seamlessly integrated into the surrounding powder. The uniform material composition ensures the structure's self-supporting nature even while submerged, facilitating the production of intricate shapes. Subsequently, excess powder can be easily removed, completing the manufacturing process.

What sets SLS printing apart is its ability to utilize more robust materials compared to conventional plastics. A prime example is the popular choice of Nylon powder, known for producing lightweight, durable, and flexible models. Unlike traditional applications limited to prototyping, SLS printing allows for the fabrication of fully functional mechanical parts, expanding the scope of practical end-use applications.

Industrial 3D Printers

As previously discussed, a remarkable aspect of 3D printing goes beyond the creation of objects seemingly out of thin air; it lies in the unprecedented scalability of the process. With an appropriately sized printer and an ample supply of materials, virtually any size of object can be produced using various 3D printing methods. This capability allows for the fabrication of objects across a broad spectrum of sizes, limited only by the dimensions of the printer and the availability of materials.

Efficient 3D printing technology is currently employed in the production of industrial-scale mechanical parts, exemplified by its application in crafting various components for passenger-grade aircraft. This innovative manufacturing approach not only accelerates the production of these components compared to traditional methods but also facilitates the use of lighter yet equally durable materials. By opting for lighter materials in aircraft construction, the strain on engines is reduced, leading to decreased fuel consumption. It is important to note that while 3D printing does not possess the capability to generate matter from nothing, it stands as a testament to our ongoing efforts to enhance accessibility and economic efficiency in the realm of crafting.

Comments